Life Cycle Assessment Verified by Independent Third Party

Article

Results of a Life Cycle Assessment performed by DuPont and verified by an independent third party provide important insights for the packaging industry.

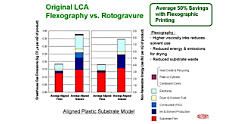

Comparing Flexo to Gravure

The first step in the Life Cycle Assessment was to compare the carbon footprint of flexo to gravure based on comparable substrate and printed area.

Flexo had a 50% savings in greenhouse gas generation and non-renewable energy consumption.

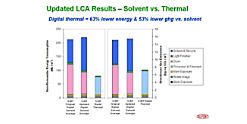

Comparing Cyrel® solvent to Cyrel® FAST

The second step in the Life Cycle Assessment was to compare the carbon footprint of solvent to Cyrel® FAST processing based on an equivalent volume of processed plates.

Cyrel® FAST demonstrated a 53% savings in greenhouse gas generation and a 63% reduction in non-renewable energy consumption.

Using ISO Guidelines

The ISO 14000 group of standards addresses various aspects of environmental management. Using ISO 14040 guidelines, DuPont performed this Life Cycle Assessment of flexographic plate imaging technologies and compared flexographic and rotogravure printing.

Related Products

Cyrel® Platemaking Equipment

Cyrel® flexographic platemaking solutions include processors, exposure units, and dryers for solvent and thermal processing environments

Cyrel® FAST Thermal Workflow

Cyrel® FAST thermal plate processing technology uses solvent-free thermal processing to produce a press-ready finished flexo plates

Flat Top Dot Workflow Solutions

DuPont offers two flat top dot workflow solutions: Cyrel® DigiFlow and Cyrel® DigiCorr

Cyrel® Round Systems

Cyrel® Round Systems offer a complete digital flexographic sleeve production solution that delivers highly precise registration and eye-catching print quality.